News Center

Newss

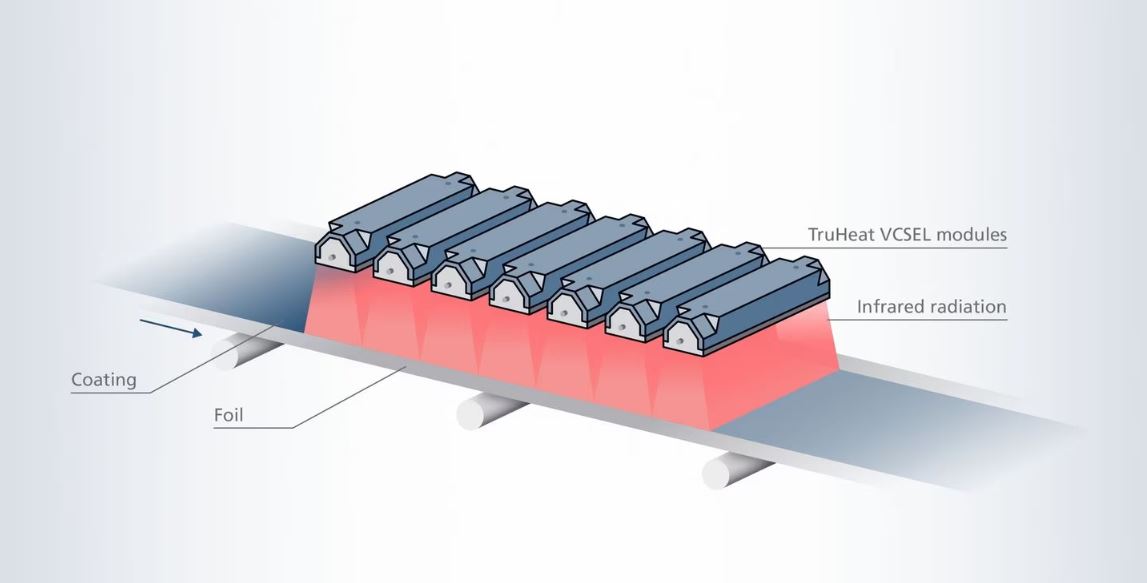

Use the Truheat VCSEL heating module to realize the high energy efficiency of the dry battery foil. // The new generation of innovation VCSEL technical supports lower power density // Through direct thermal transmission, use the VCSEL heating system to improve the battery manufacturing process and product quality // for it for use for it for use for it for use for it for use for it.areaTruheat VCSEL heating module of heating and electric vehicles heating modules

Ulm/Francisco, San Francisco, January 29, 2024-Trumpf Photonic Components, a global leader of industrial laser heat treatment VCSEL solution, will show its use at Photonics West 2024 held in Francis 2024, Francisk, USA.Development of the latest TRUHEAT VCSEL product in regional heating and electric vehicle applications.The VCSEL -based laser heating system provides direct, uniform and regional controlling heat treatment for the industrial process."One of the examples we will show the dry battery foil is driedofThe next generation of Truheat VCSEL system can provide higher efficiency and support lower power density.GUDDE added: "Due to the uniform heating and lighting area control, the processing speed is fast, the area is small, and the carbon dioxide emissions are low. Therefore, the quality of the process is high, which is the benefit of our customers.

New for battery foil dry applicationtypeTruheat VCSELLaser heating system

The drying of the electrode coating is a delicate process. Due to the very large and inefficient streaming oven, most of the energy sources in lithium -ion battery manufacturing.Laser drying provides several advantages, such as improving energy efficiency, reducing the area of land and increasing process control.Therefore, the TRUHEAT VCSEL laser heating system has been developed to realize the uniformly dry and large surface with a relatively low power density.The Truheat VCSEL laser heating system is based on the latest generation of multi -end VCSEL arrays. The heating system is optimized for thermal design and is equipped with efficient driving electronic devices.The wavelength of 980 nm isallThe battery electrode material is strongly absorbed, so it supports high drying efficiency.

The Truheat VCSEL laser heating system adopts a modular design and has an independent area.This enables strict control of various lighting areas, so that not only does the best uniformity, but also the customization of the strength distribution.For example, Lower or higher at the edge of the coating.

Visit Tong KuangPhoton element in Photonics West 2024833 booth

This press releaseProvides digital photos with printed resolution.They can only be used for editing.It can be used for free when the credit card is provided in the form of "photo: trumpf".Graphic editing is prohibited (except for cutting the main body).Other photos can be accessed in the TrumpFF media pool.

The TruHEAT VCSEL heating solution made by Limei can achieve more efficient production in various process steps.

The VCSEL diode used in the VCSEL heating system is manufactured in the clean room facilities of the Kuyou photon component Ulm headquarters.The assembly of the heating module is completed at Aachen's customer application center.

In the process of drying the battery foil, the VCSEL heating system can effectively dry the active substances on the electrode without any energy loss, which is due to its direct thermal treatment.

High -power infrared VCSEL heating system provides scalable power and can be accurately adjusted.